- HOME

- SERVICES

-

PRODUCTS

-

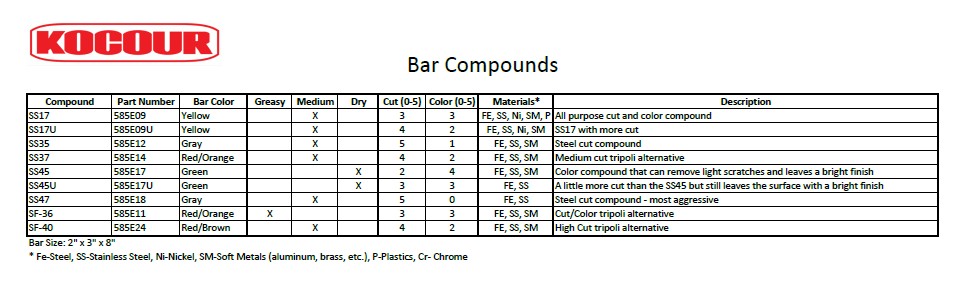

AUTOMOTIVE DETAILING

- Detailing Buffing Compound Buffing Wheels

Electroplating

- Hull Cell Testing - Plating Plater's Accessories

-

- ABOUT US

- DOWNLOADS

- USED EQUIPMENT

- Contact

- SEARCH

-

PRODUCTS

-

AUTOMOTIVE DETAILING

- Detailing Buffing Compound Buffing Wheels

Electroplating

- Hull Cell Testing - Plating Plater's Accessories

-

- HOME

- ABOUT US

- SERVICES

- DOWNLOADS

- USED EQUIPMENT

- SEARCH

- Contact